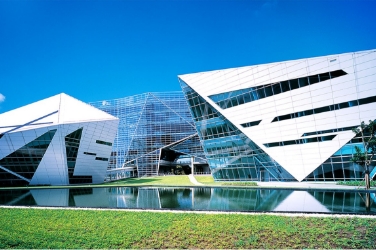

The Thai Metal Trade Knowledge

Center is a seminar venue for TMT, one of the main steel manufacturers in

Thailand, and an education center for the public, architects and engineers, to

learn about steel products, materials and production.

Four buildings designed to

accommodate the entire program which includes a lobby, seminar rooms, career

services, an oversized meeting room, three seminar rooms, offices and parking.

The first building houses the meeting and seminar rooms, the second houses the

offices, the third is given over for the general public while the last is for

services. These four buildings are arranged around a central water feature that

helps reduce the interior space and the need mechanical ventilation.

The buildings are grouped to the

east of the site, preserving a large green area to the west for future

expansion. The project owner, with his great appreciation for art, wanted the

building complex to stand as a work of art in its own right. Following this

directive, wood-patterned aluminum composite panels were selected to emphasize

the curved form of the auditorium. By night, when the meeting rooms are

beautifully lit, the suspended art work in the foyer becomes even more spectacular.

Steel was used, whenever possible,

as the primary building material in order to reflect TMT business. Many of the materials

used were TMT products, including the metal roof structure, metal cladding and

metal decking. Glass was selected to compliment the steel structure and to

communicate a contemporary architectural language. All four buildings use

structural steel framing with reinforced concrete slabs at ground level and

reinforced concrete over metal deck on the upper level. All the steel framing

for the project was prefabricated on site and then assembled using nut and bolt

connections.

Metal cladding and aluminum

composite panels with a wood pattern are used for the walls in the main meeting

room. Steel painted doors are mounted in powder-coated aluminum frames. With

the decision to expose the building services and use an open ceiling design, a

lot of input was required from the contractor in order to create high-level

shop drawings prior to construction. The short time-frame for construction also

influenced the decision to develop a system of prefabricating the principal

structural frame; while work on the ground was still progressing, assembly of

the steel structure could begin, thus saving a significant amount of time

usually spent on structural preparation.

Thai Kajima

In 1980, Prabhakorn received his Bachelor of Architecture degree from Chulalongkorn University. He continued his education at the Catholic University of America in Washington DC, where he graduated with a Master of Architecture degree in 1984. Whilst in Washington DC, Prabhakorn worked at Robert Schwinn & Associates in Maryland before returning to Thailand and joining A49 in 1985. At A49, he has been responsible for a wide range of projects ranging from mega complexes and high-rise buildings to houses. Most of these are located in Thailand, whilst others are located in other countries in the region, including: China, Malaysia, Singapore and Vietnam. His work has also extended outside that region, for example, to the United Arab Emirates and India. All add breadth to the A49 portfolio of work. His main role has been to establish major policies, design concepts and strategic planning initiatives. He was appointed as President of Architects49 Phuket in 2005 and President of Architects49 International in 2006.

Prabhakorn actively served the Association of Siamese Architects (ASA) as its Head of Public Relations from 1992 to 1994, as its Vice President of Foreign Affairs from 1995 to 1997, and as the President of ASA during 2002-2004. He has also participated in many subcommittees for both the ASA and the Architect Council of Thailand (ACT). He is an active Council Member of the ACT, with his present duties for them extending into 2018. He has been an Honorary member of the Japan Institute of Architects (JIA) since 2003.

Prabhakorn has been a key member of A49 since its foundation, and has the honour of being trusted by Nithi Sthapitanonda (the Founder of A49) to be President and Managing Director of 49Group.

In 1980, Prabhakorn received his Bachelor of Architecture degree from Chulalongkorn University. He continued his education at the Catholic University of America in Washington DC, where he graduated with a Master of Architecture degree in 1984. Whilst in Washington DC, Prabhakorn worked at Robert Schwinn & Associates in Maryland before returning to Thailand and joining A49 in 1985. At A49, he has been responsible for a wide range of projects ranging from mega complexes and high-rise buildings to houses. Most of these are located in Thailand, whilst others are located in other countries in the region, including: China, Malaysia, Singapore and Vietnam. His work has also extended outside that region, for example, to the United Arab Emirates and India. All add breadth to the A49 portfolio of work. His main role has been to establish major policies, design concepts and strategic planning initiatives. He was appointed as President of Architects49 Phuket in 2005 and President of Architects49 International in 2006.

Prabhakorn actively served the Association of Siamese Architects (ASA) as its Head of Public Relations from 1992 to 1994, as its Vice President of Foreign Affairs from 1995 to 1997, and as the President of ASA during 2002-2004. He has also participated in many subcommittees for both the ASA and the Architect Council of Thailand (ACT). He is an active Council Member of the ACT, with his present duties for them extending into 2018. He has been an Honorary member of the Japan Institute of Architects (JIA) since 2003.

Prabhakorn has been a key member of A49 since its foundation, and has the honour of being trusted by Nithi Sthapitanonda (the Founder of A49) to be President and Managing Director of 49Group.

In collaboration with Landscape Architects 49, we have extensive experience in master planning and urban design. We have worked for both government and private sectors from large urban development to planning of new university campus.